Table of Contents (click to expand)

A battery management system is built into an appliance to monitor and optimize the health and performance of the battery pack.

Batteries have been around for some time now, and with the evolution and ‘compaction’ of technology, even the most power-intensive devices are looking to migrate to wireless iterations. Today, batteries are no longer restricted to small cells that you snap into the back panel of handheld devices; they are progressing towards powering much bigger appliances that the modern world demands.

Cell Vs Battery

A cell is a single device in which electricity is generated by a chemical reaction. A collection of such cells is known as a battery. Outwardly, a battery may look like a very large cell, but it is actually a series of cells all connected together.

Batteries are used in places where the electrical demand is high, in terms of voltage, current or even the duration for which it must be supplied.

Battery Packs And Battery Modules

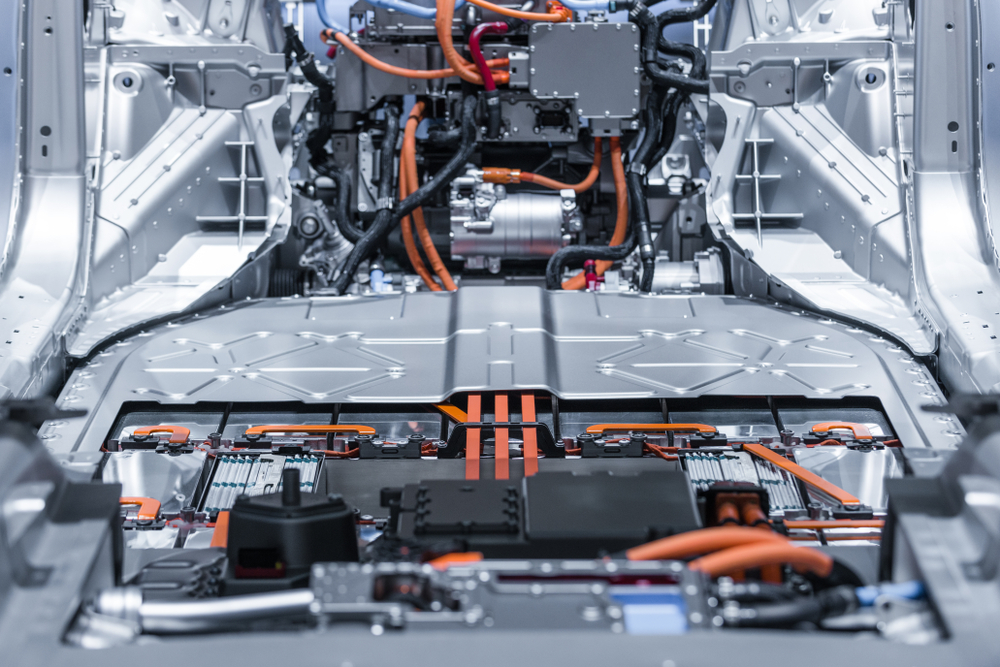

Even the most energy-intensive electronic systems are now being designed to be portable. In such scenarios, batteries can no longer be passive components that simply supply electricity. They must actively coordinate with other parts of the system and supply users with useful information.

Batteries are therefore coupled with software, and sometimes, their own temperature control system, and then consolidated into one enclosure. Such a unit is known as a battery pack. When the battery pack is large, the batteries are arranged in smaller and easily serviceable units called modules.

Also Read: AA Vs D: Why Are There Different Types Of Batteries?

Battery Management System (BMS)

As with everything else, the longevity of a battery pack depends on how well it is used throughout its lifecycle. Since batteries by themselves cannot do much more than generate electric current, they’re connected to an electronic chipset with software built into it. This system is known as the battery management system and is responsible for monitoring and improving the life of the battery pack.

What Does The BMS Monitor?

Simply put, the battery management system monitors the state of charge and the overall health of the battery. This is done by ensuring that all batteries within the pack are charged and optimally depleted by usage (discharged), with no single unit taking on more of a load than the others.

The state of charge (SOC) of a battery refers to its current capacity to hold charge as a percentage of its rated capacity. A battery’s maximum SOC reduces over time, which reduces the amount of charge it can hold. Similarly, the state of health (SOH) is the ratio of the battery’s maximum capacity of charge to the charge capacity of a fresh battery of similar specifications. Also, if there is some fault in the appliance using the battery pack, the BMS protects it by disconnecting it from the surge, thereby isolating it from potential damage.

Also Read: What Are The Different Methods To Estimate The State Of Charge Of Batteries?

Components Of BMS

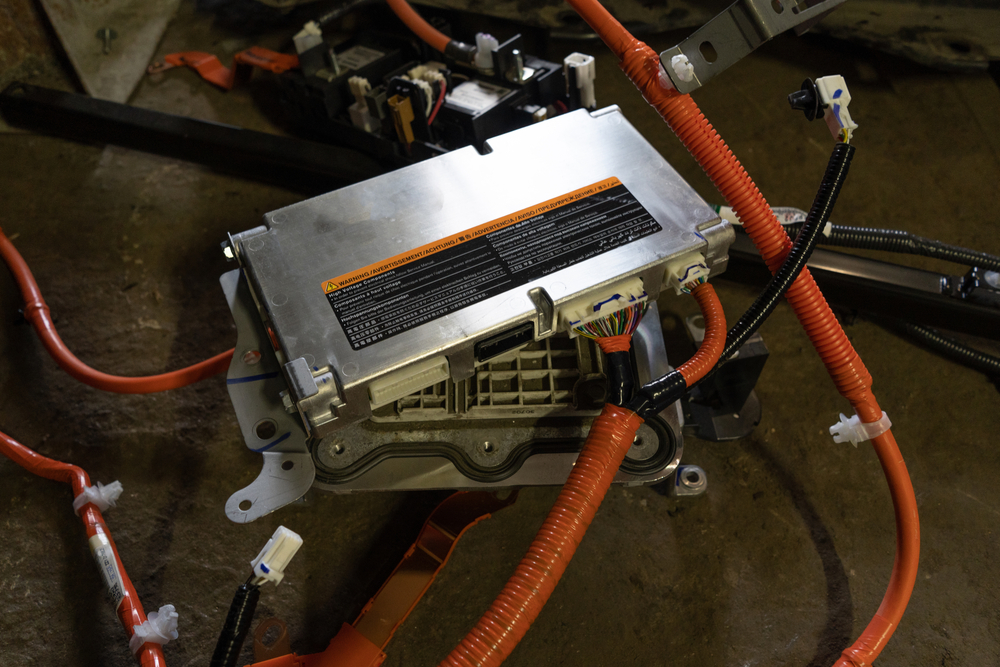

Battery management systems are complex electronic architectures that can be decomposed into smaller ‘building blocks’, each designed to serve the battery in some way.

Components And Functions Of BMS

The complex BMS architecture is composed of various components. It includes a temperature monitor, a voltage monitor, and a charge monitor. These provide information regarding the battery temperature, state of health, and charge, respectively. It is used by the battery isolation FET (field effect transistors) to control the flow of current within the battery pack.

While the individual components of a BMS give some insight as to how it works, it is important to know why a BMS is needed at all. After all, they’re still the new kid on the block… batteries have been in use for decades!

- Safety: When batteries generate more heat from chemical reactions than they can vent, catastrophic explosions can occur, resulting in fire. BMS helps avoid this by preventing the flow of excessive current through the battery when temperatures are higher.

- Performance optimization: BMS initiates cell-balancing procedures when various cells in the pack are at different states of charge. This prevents the lower-capacity cells from being fully discharged, as their higher-capacity counterparts transfer their charge to attain equilibrium. Similarly, the overcharging of low-capacity cells is prevented by ‘spilling’ the extra charge over to the higher-capacity cells.

- Battery health monitoring: Battery health is monitored by comparing how a battery performs today against what it performed like when it was new. This benchmarking determines the drop in the efficiency of the battery with use over time. By running batteries optimally through their charge and discharge cycles, the BMS ensures that the life of the battery pack is maximized.

Can Batteries Be Made To Last Longer?

When using batteries in a more traditional way, there is always room for uncertainty. However, adding a BMS changes the way batteries charge and discharge. This helps in ensuring that the batteries do not face any overload, which reduces their life.

But if BMS improves battery life, why don’t all appliances utilize such a system?

The biggest reason is the cost of adding a BMS, which would far outweigh the cost of simply replacing the batteries, making such a strategy uneconomical. A BMS is commonly used in appliances that use battery packs, where the cost of the battery pack comprises a significant percentage of the total appliance. Those types of appliances are also expensive, justifying the cost of the BMS module.

So, while the name BMS might not be thrown around casually anytime soon, at least you’ll know what goes on inside the battery pack of the next electric car you see!

How well do you understand the article above!

References (click to expand)

- Bareño, J., Dietz Rago, N., Dogan, F., Graczyk, D. G., Tsai, Y., Naik, S. R., … Bloom, I. (2018, May). Effect of overcharge on Li(Ni0.5Mn0.3Co0.2)O2/graphite lithium ion cells with poly(vinylidene fluoride) binder. III — Chemical changes in the cathode. Journal of Power Sources. Elsevier BV.

- Krieger, E. M., & Arnold, C. B. (2012, July). Effects of undercharge and internal loss on the rate dependence of battery charge storage efficiency. Journal of Power Sources. Elsevier BV.