Table of Contents (click to expand)

Medicines can be made by synthesizing chemicals with potential therapeutic effects or by extracting pharmacologically active chemicals from nature.

There was a time when humans fell like flies to diseases like cholera and malaria. Fortunately, thanks to science, we now have an impressive arsenal of medicines to fight the countless diseases that plague our species.

It has taken many decades and careers of research and development, a significant investment of resources, and brilliant minds, and luck to make them. I, for one, believe that the effort was worth it. It is the manufacture and extraction of medicine that gives us the luxury to go about our lives without the fear of diseases that once decimated our ancestors.

So, how exactly are these drugs—the pills and capsules, suspensions and syrups, gels and creams, injectables and inhalables—actually made? And perhaps more importantly, how expensive is it to produce them?

First, let’s start with the basics.

What Are Medicines?

Medicines are substances that are used to treat or prevent diseases and alleviate their symptoms. They can be chemically synthesized in laboratories or obtained from available natural resources, such as plants and minerals.

Painkillers like aspirin are chemically produced, whereas antibiotics such as penicillin are extracted from the fungal species Penicillium chrysogenum. Antibiotics can also be extracted from bacteria; for example, streptomycin comes from Streptomyces griseus.

Active Pharmaceutical Ingredient (API) And Drug Target

All these special compounds, whether synthesized or extracted, are referred to as the active pharmaceutical ingredient of the medicine. Every medicine has a unique compound (or combination of compounds) that achieves the desired curative or preventive effect.

When a medicine enters the body, the active ingredients of the drugs interact with biochemical components in our body to achieve the intended effect at the site or organ known as the “drug target”.

Also Read: How Do Medicines ‘Know’ Where To Go?

Drug Development: How Are Drugs Made?

The Chemical Way

Chemicals, either organic or inorganic, are mixed together, and after a series of complex chemical reactions, we get medicine that possesses unique pharmacological properties.

These chemical reactions take place in gigantic reaction tanks and are either heated or cooled, after which they are mixed in a controlled manner. After the reaction is complete, the leftover chemicals are boiled off by excessively heating the concoction. The remaining product of the reaction is cooled down until a powdery or crystalline substance is formed.

It is this powdery or crystalline substance that contains the active pharmaceutical ingredient that is carried forward to the next stage—drug formulation.

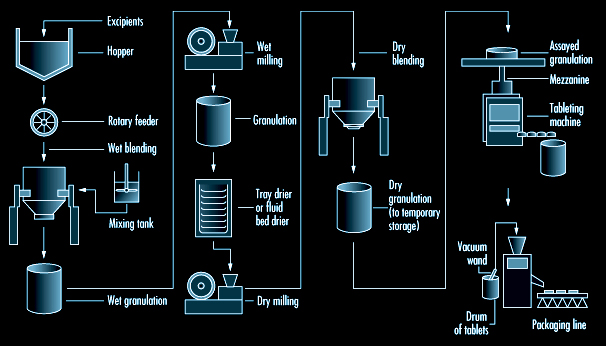

In drug formulation, the active ingredient is mixed with water and binding agents in a large mixer to form the medicinal compound. Based on the chosen delivery method, this mixture is dried and either compressed into tablets, processed into a cream or gel, or bottled in injection vials.

If you are interested in a visual walkthrough of the drug manufacturing process, AstraZeneca has an informative video on drug manufacturing.

The Natural Way

Looking back at history, drug discovery mainly stemmed from plants. Ancient Egyptians used opium as a painkiller, Indians used neem for dental and oral health, and turmeric was famous for its antiseptic and antibiotic properties.

Even today, nature inspires drug discovery and development.

Instead of using the whole source, we seek and isolate that one active pharmaceutical ingredient from either the plant, microorganism, animal or mineral, extract it and then package it into pharmaceutical products.

Making Pharmaceutical Products

Let’s look at how penicillin is made as an example. Penicillin is an antibiotic derived from a fungus that has the ability to make penicillin coded into its DNA. This particular chunk of DNA is cut out and inserted into the DNA of a commonly available and low-maintenance bacterium, such as E.coli (found in our poop). The bacteria are then cultured, i.e., grown in bulk, inside a reaction tank. Once they start producing penicillin, it is extracted from the culture and then filtered, purified and packaged in tablets.

Another example of a laboratory-made therapeutic is artificial insulin—the hormone used to lower blood sugar in diabetics.

Quinine from the plant Cinchona officinalis is an example of medicine derived from plants. Quinine is a drug that treats malaria. You may have heard of its more advanced form—hydroxychloroquine.

The bark of this plant is crushed and dried completely before being powdered. Quinine is then extracted from the dried bark powder and purified.

Also Read: Will Future Drugs Come From Bugs?

A Final Word

Drug discovery isn’t easy or cheap! Researchers spend years or even decades creating chemicals with the hope that one molecule out of hundreds might end up being a cure. Now, we also get a little help from computers, which create models of new drugs that have structures that make it easier for the drug to bind to its target. We call this “Computer-Aided Drug Design,” or CADD for short.

Pioneering research suggests new and improved technologies that will help boost the chemical drug synthesis sector even further. Who knows, perhaps AI will simply take over the entire process of drug development in the future, and make life easy for all of us.

Even with so much money and effort, there is still a high chance that the drugs won’t work as they should or how we intend. In fact, there is currently a 90% failure rate in drug development. Hopefully, we’ll see a significant decline in this percentage in the coming decades.

How well do you understand the article above!

References (click to expand)

- Prakash, B., Kujur, A., & Yadav, A. (2018). Drug synthesis from natural products: a historical overview and future perspective. Synthesis of Medicinal Agents from Plants. Elsevier.

- Berdigaliyev, N., & Aljofan, M. (2020, May). An overview of drug discovery and development. Future Medicinal Chemistry. Future Science Ltd.

- Chapter 79 - Pharmaceutical Industry - www.ilocis.org:80

- Patrick G. L. (2018). An Introduction to Medicinal Chemistry. Oxford University Press