Table of Contents (click to expand)

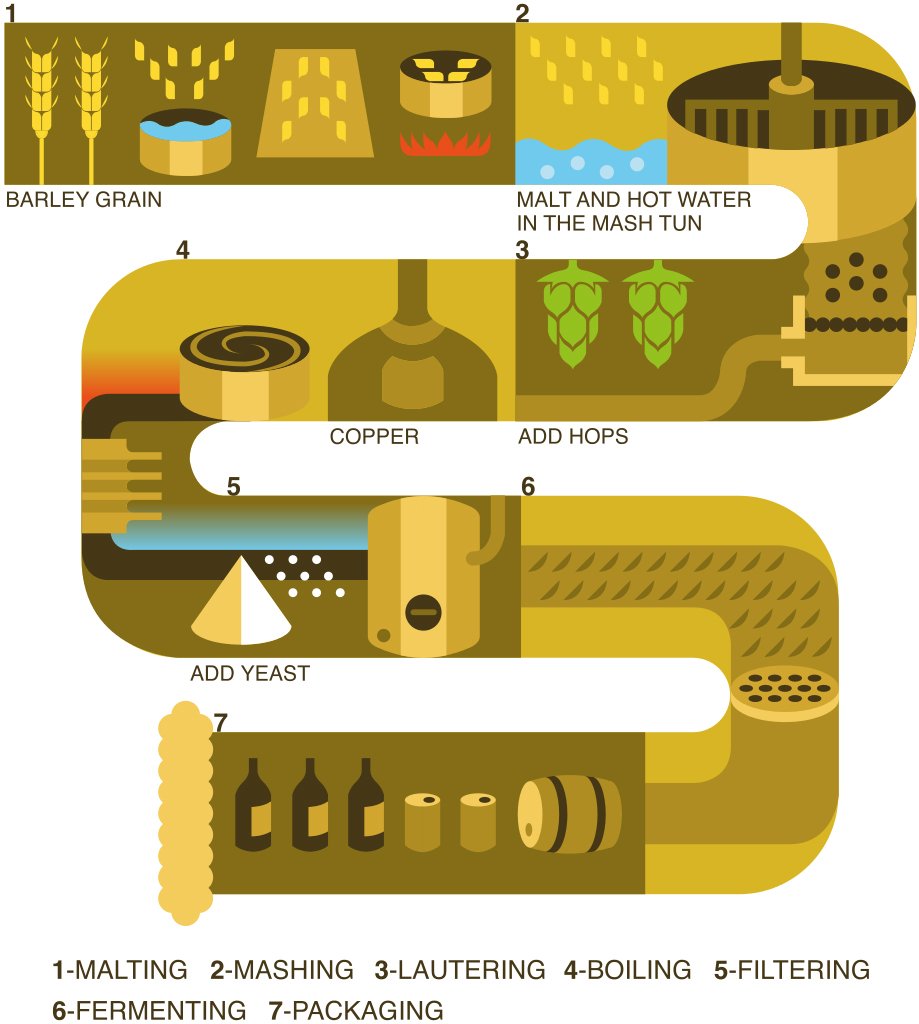

Beer is made from malted cereal grains, hops, pure water, and brewer’s yeast. The grains are soaked in water and then germinated to release enzymes. The malt is then roasted and crushed, and the mash is mixed with warm water and allowed to sit so the solids can settle. The liquid is then filtered and boiled with hops, and the yeast is added to the mixture. The beer is then filtered and transferred to aging casks, where it is pasteurized to kill the remaining yeast.

The class of beverages known as the beer has been brewed in some form for thousands of years. Beer is obtained from the fermentation of malted cereal grains. Brewing today has become a multi-billion dollar industry, although it came from very humble beginnings as little more than a cottage craft. The most beer consumed by any country on a per capita basis is in Germany, with an estimated 40 gallons consumed per person each year. We know it’s delicious, but let’s take a look at the raw materials required to make this popular beverage.

Raw Materials

The fundamental ingredient in beer is the cereal grain used to make it. The cereal grain used for the production of beer is usually barley, with the occasional addition of corn or rice. The other raw materials needed for beer production are hops (also known as Humulus lupulus), pure water and brewer’s yeast. Hops are a special kind of cultivated perennial hemp. The useful portion of the hops is the cones, which are sticky and develop after blooming. Each of these ingredients plays a crucial role in the flavor, color, carbonation, alcohol content and other subtle changes in the characteristics of the beer. The handling of the grains, as mentioned above, is highly imperative for determining the overall quality of the beer.

Around 16 kg of barley malt and 7 kg of grain are used to make a single 31-gallon barrel of beer. Large amounts of pure water are required not only in the brewing process but also for the maintenance of the brewing equipment. If the water is in any way contaminated, i.e., containing lime or iron, it will interfere with the fermentation process and lead to the discoloration of the beer. However, the real beer maker in the whole process is the yeast. Yeast is a type of fungi that reduces the sugar to alcohol and enables the process of fermentation.

Also Read: Does Your Bread Contain Alcohol?

Manufacturing

Fully ripened barley grains are soaked in cold water to the point where they are completely saturated. The water is changed once a day, and every 45-72 hours, the grains are taken out and placed in shallow tanks. The grain is aerated and stirred, which causes it to germinate, releasing key enzymes, such as malt diastase. Malt diastase converts the starches contained in the grain to sugar for fermentation. As soon as the germination is complete, a process that takes around six days, the grain is roasted to stop the germination process. The exact point at which the roasting starts and ends affects the flavor and color of the beer. At this stage of the process, the product is called malt.

The malt is then crushed with the help of iron rollers and transferred to the mash tank. This tank is a large copper or stainless steel vessel that mixes the malt with warm water until it has a porridge-like consistency. This mixture is called mash. After mixing this with similarly prepared cereal grains, the temperature of the mash is raised incrementally from 38-77°C so that the enzymes start reacting. The enzymes break down the starch in the grain and convert it into simple sugars. Later, the yeast will turn the sugars into alcohol. Once this step is complete, the mash is allowed to sit undisturbed so the solids can descend to the bottom of the tank.

The liquid present in the mash is transferred into another tank called the lauter tun. This is accomplished by drawing the liquid out through the bottom layer of mash solids, which acts as a filter. Hot water is then added to the top of the mash tank to rinse off the remaining liquid, which is now called wort. The substantial remains of the grain are dried and sold by breweries as animal feed. The wort travels on to the brew kettles, where it is boiled for sterilization purposes and where the carefully prepared hops are added. The addition of the hops is crucial because they contribute to the bitterness of the beer. The brew kettles are the most impressive pieces of equipment in the process. Gleaming copper, they can be as wide as 3.5 m in diameter and two stories high. Steam usually provides the heating energy to these brew kettles. After brewing is complete, the finished wort is filtered once again and pumped to the fermentation tanks.

In the fermentation tanks, the atmosphere must be closely controlled so that no other organisms can flourish in the environment. Carefully maintained yeast is added to the wort, and the temperature of the mixture is slowly reduced throughout multiple days to between 10-15°C. In this temperature range, the yeast grows, consuming the sugar in the wort, and bubbles of carbon dioxide begin to form. The wort has now become beer. The new beer is filtered and transferred once more into the aging casks, where the temperature is controlled at 33°F (°C) for 2-24 weeks. A shorter storage time produces a pale lager beer, while European lagers (also called Pilsners) are aged longer to increase the alcoholic content.

Once the aging process is complete, the beer can be pasteurized to kill the remaining yeast and prevent further alcohol production. This is accomplished by heating the beer above 57°C. Pasteurization, however, is not used in the production of good draft beers. These beers are also known as “ice” beers since they must be kept refrigerated to preserve their flavor and slow the activity of the remaining yeast. Many consider draft beers best in both aroma and taste.

Whether packaged into cans, bottles, or kegs, beer is always moved gently through the maze of piping in the bottling area. This is done to preserve the natural carbonation. During bottling, additional carbon dioxide gas from the fermentation kettles is used to further improve the aroma of the beer. High-speed packaging lines can process thousands of cases of beer per day, and with modern computerized control, the inventory can be meticulously tracked throughout the distribution network. Most beer is delivered from local distributors who have purchasing contracts with major breweries. So the next time you take a chilled pint of beer, you will know the process it to took to reach your hand.

Also Read: How Do Microbes Help Us Make Chocolate?

How well do you understand the article above!