Table of Contents (click to expand)

A cylindrical or elliptical tanker is better able to withstand pressure than a rectangular one, is more stable, and is easier to clean.

While driving around the city, you have surely seen oil/water tankers hundreds of times. Although tankers come in different sizes, have you noticed the rather interesting thing that’s common in almost all tankers? All liquid-carrying tankers are cylindrical in shape.

Wouldn’t a rectangular tank be able to carry more volume than a cylindrical one? Also, it seems like a rectangle-shaped tanker would be easier to manufacture on a large scale. With that in mind, why do these trucks carry cylindrical (or elliptical) tankers?

Tank Trucks

A vehicle that’s specially designed to carry liquefied loads, such as water, oil or gases is referred to as a tank truck (or tanker truck). Some of these tank trucks, especially the pretty large ones, are quite similar to railroad tank cars that you’ve likely seen chugging along on railway lines.

There are many variants of tank trucks, depending on the type of liquid that needs to be transported. Tank trucks can be large or small, pressurized or non-pressurized, insulated or non-insulated and so on.

Most, if not all, tank trucks that carry liquids are of a cylindrical/elliptical shape. Why is that?

Also Read: How Do Train Wheels Turn?

Reasons For The Cylindrical Shape Of Oil/liquid Tankers

No Weak Spots

Firstly, a cylindrical container doesn’t have ‘weak spots’ that need reinforcing, which would translate to using more material to build the tanker. In contrast, a rectangle/square has corners and flat sides, which create weak points for pressure. In other words, a rectangle-shaped container would fail faster than a cylindrical one upon experiencing a great deal of pressure.

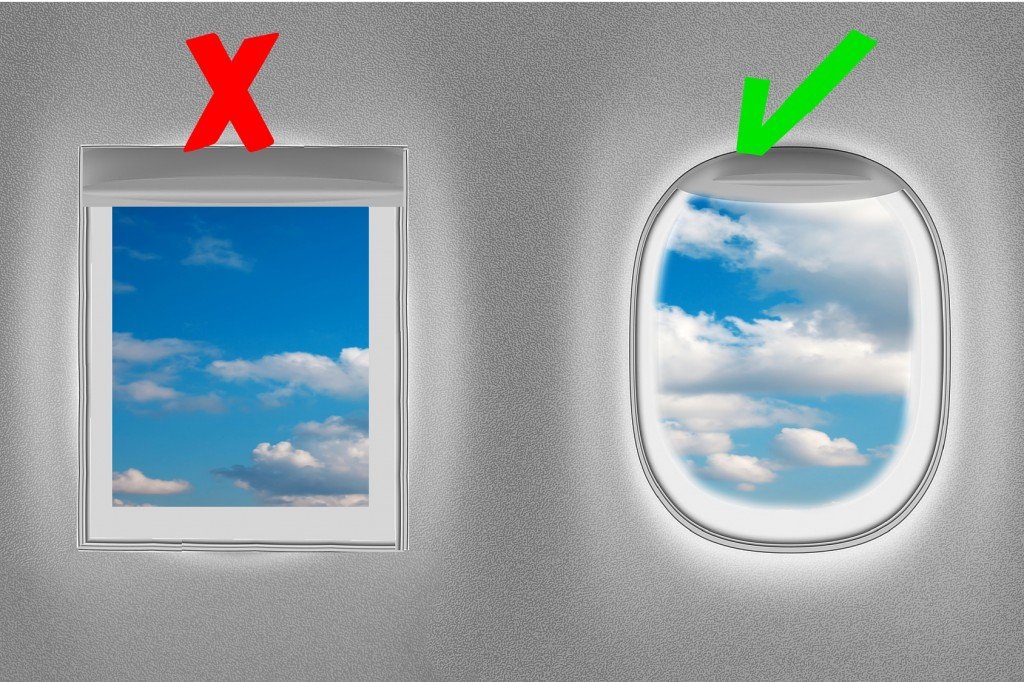

That’s the same reason why windows in commercial airplanes have rounded corners, rather than being perfectly rectangular/square-shaped. We have a whole different article on that topic, which you can read here.

Spherical shapes are the best for housing liquids, as a sphere lets you store the maximum volume for a given surface area. However, spheres are not easy to transport, so the next best choice becomes a ‘long’ sphere, i.e., a cylinder or ellipse.

Stability

The stability of the vehicle, especially one carrying liquids like oils and liquefied flammable gases, is of paramount importance. As such, you want to choose a shape whose center of gravity is as close to the ground as possible. Rectangles and squares are poor choices in this regard, as the center of gravity of a rectangular tanker would be at a greater height than that of a cylindrical tanker.

Sloshing Liquid

There’s also the problem of sloshing of the liquid. You see, when a truck accelerates/slows down, the liquid in the tanker is bound to slosh around (i.e., move to and fro) within the tanker in accordance with the law of inertia, i.e., an object at rest stays at rest and an object in motion keeps moving until acted upon by an unbalanced external force.

This sloshing effect is referred to as ‘surge’ in industry lingo. In order to prevent/minimize the effect of this surge, many tankers have sheets of metal inside them that reduce the front-to-back surging. This is one of the reasons that good tanker drivers gradually slow down their trucks while maneuvering a turn or coming to a halt.

Although a sphere is the best shape to counter surging, as we discussed, that’s not an easy shape to transport. Thus, cylindrical – the next best – is preferred.

Liquid Extraction And Maintenance

A cylinder, as you can imagine, is more favorable when it comes to extracting the liquid contents of the tanker, as it lets the liquid funnel down to the bottom of the tank.

A rectangle, on other hand, wouldn’t be a great choice in this regard. This is the same reason why most bathroom sinks are NOT rectangular.

Lastly, rectangular tankers would be more difficult to clean than cylindrical ones, as traces of liquid would get stuck in the corners, making them harder to sanitize. Cylindrical/elliptical tankers present no such cleaning or sanitary problems.

Also Read: Why Do Cooling Towers Have Such A Unique Shape?

How much do you know about trucks and cylindrical tankers?