Table of Contents (click to expand)

The rubber bands lose their elasticity because the polymers and plasticizers in rubber begin to oxidize over time, and exposure to ozone (which is present in all air to some degree) is largely responsible for this oxidization battle with rubber.

There is something strangely fascinating about rubber bands. Whether we’re using them to hold back our hair, organize papers, or wrap around our pointer finger for a cheeky snapshot, the elasticity of rubber bands allows them to perform many functions that we rely on every day – especially our fruit-cutting needs.

Their predictable stretch and elastic embrace help to keep things secure, but nothing lasts forever, and you’ve surely noticed that over time, rubber bands start to lose that sexy stretch. Eventually, they’re just useless rings of worn-out rubber, or they snap under certain conditions.

The question is, why does this change happen? Why do rubber bands lose their elasticity?

The Science Of Rubber

Rubber isn’t a manmade creation, although we do use it in countless applications to make our life easier. In fact, natural rubber is a special type of chemical compound called an elastomer, composed of unique molecules that can stretch to nearly double their normal length. Various forms of rubber in human use have been around for thousands of years, and likely began in Brazil, where the “rubber tree” (Hevea brasiliensis) is found.

Natural rubber comes in the form of a runny, white milky substance called “latex” and can be found in very small quantities in other plants, but rubber trees hold huge amounts of rubber molecules in a colloidal suspension (roughly 30%), making it the most popular and efficient source for extracting rubber.

When the ancient residents noticed the unusual bouncing and stretching properties of the substance, they began using it much as we do now – to make balls for sports, waterproof shoes, and protective coverings for their possessions. Early explorers saw this remarkable substance and brought it back to Europe, where it quickly gained popularity and was improved.

Fast-forward a few thousand years, and we have perfected our use of natural rubber. Recognizing that unprocessed rubber didn’t have nearly as much resilience or as high of a stretch ratio, researchers combined the natural elastomers found in rubber with many different oils and substances to improve the properties. One of the most important breakthroughs was the use of plasticizers, which are small molecules that can improve flexibility and stretching. The chains of polymers can slip past one another more easily and stretch without straining, because these “spacer” molecules prevent rigidity and unnecessary bonding between the polymer chains.

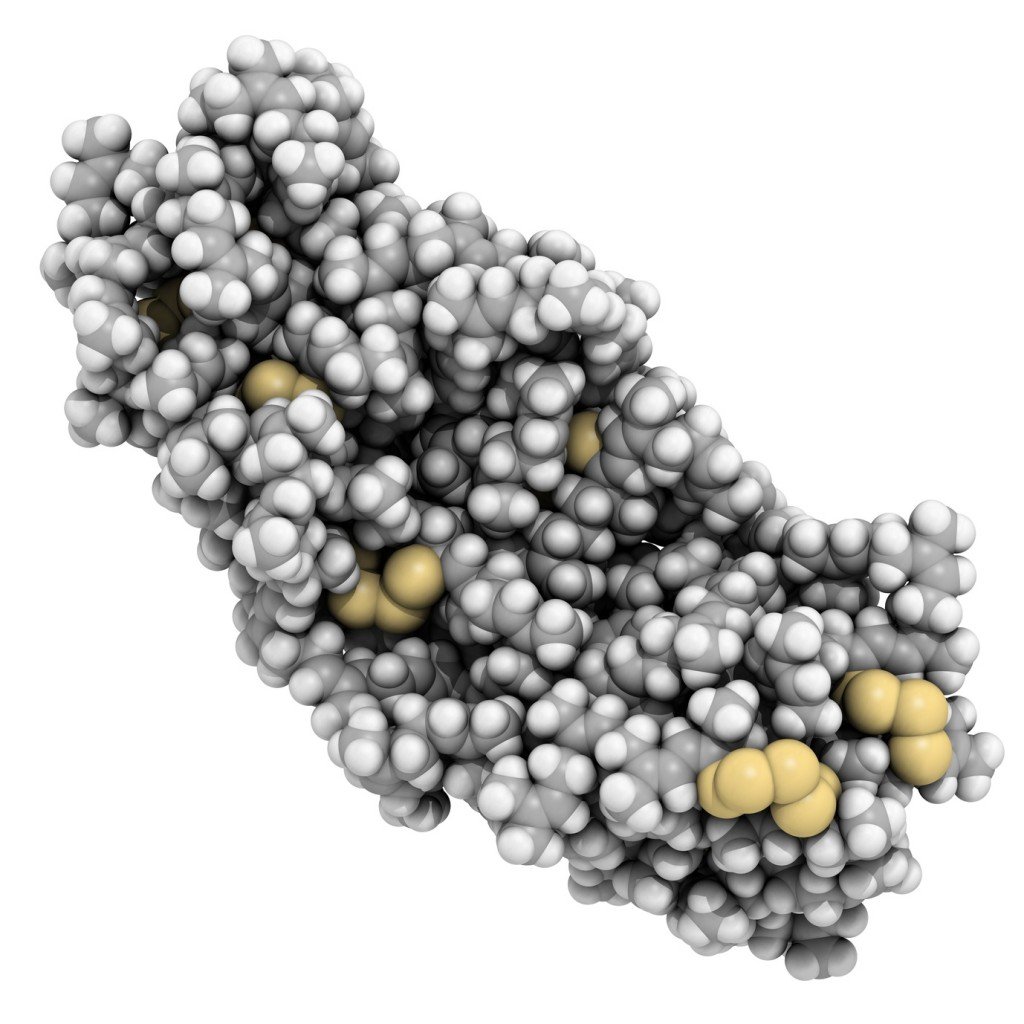

Vulcanized rubber is another altered form of natural rubber that we see in everything from the tires on our cars to our favorite bowling balls. Vulcanized rubber was only developed in the 19th century, and involves mixing sulfur or other accelerators into the polymer mix of rubber to strengthen the substance and make it less susceptible to breaking down. The sulfur atoms act as cross-links between the chains, permitting extreme stretching without snapping, and adding strength and integrity to the material.

Also Read: Why Does A Rubber Ball Bounce Back While An Iron Ball Doesn’t?

What Is The Weak Point Of Rubber? Why Does It Lose Its Stretch?

As with most things in nature, there is a breaking point, and rubber is no exception. Untreated natural rubber can be flimsy and easy to pull apart or deform, which is why synthetic rubbers and “treated” rubbers are predominant nowadays. However, plasticizers and other compounds added to rubber do have vulnerabilities, particularly light and oxidization.

When the elastomers and plasticizers begin to oxidize over time, those materials stop performing their functions and providing the elasticity that we know and love in our rubber products. The snap-back benefit of a rubber band begins to disappear as those natural chemicals begin to break down. In natural rubber, oxygen exposure will begin to break down the double bonds within days, leaving a crumbly mess; that is why rubber has been heated and treated for thousands of years – to slow the inevitable breakdown.

Exposure to ozone (which is present in all air to some degree) is largely responsible for this oxidization battle with rubber, but that isn’t the only culprit. Light (particularly UV radiation) is another arch-enemy of elasticity and rubber. Leaving rubber out in the sun too long can cause the polymers and plasticizers to deteriorate, causing that bounce-back aspect of rubber to disappear.

Finally, the polymers and molecules in rubber prefer to be “warmed” up to have maximum flexibility and resilience, so stretching rubber out in cold weather can sometimes be dangerous. When the temperature is low, the molecules don’t move past one another as readily, and can make rubber brittle and prone to snapping.

From all of that information, it seems like the best thing to do with your hair ties is to never stretch them too far, keep them at room temperature, stay out of the sun, and don’t expose them to any oxygen. Simple, right?

How well do you understand the article above!