Ultimate tensile strength or simply, tensile strength, is the measure of the maximum stress that an object/material/structure can withstand without being elongated, stretched or pulled.

What Is Ultimate Tensile Strength?

Tensile properties of a material indicate how it will react to forces applied on it in tension. As you can imagine, some materials break when a great deal of force is applied to them, while others get elongated or physically deformed in some other way. Materials that break very sharply are said to undergo a ‘brittle failure’.

On the other hand, there are some materials that can handle/withstand a great deal of stress while being pulled or stretched before breaking. The term ‘ultimate tensile strength’ (or UTS) is used to refer to the maximum stress that a material can handle before becoming elongated, stretched or pulled.

Often shortened to just tensile strength (TS) or ultimate strength, ultimate tensile strength quantifies the force required to pull a material to the point where it breaks.

Also Read: What Is Yield Strength?

How Ductile Materials Behave When Stress Is Applied

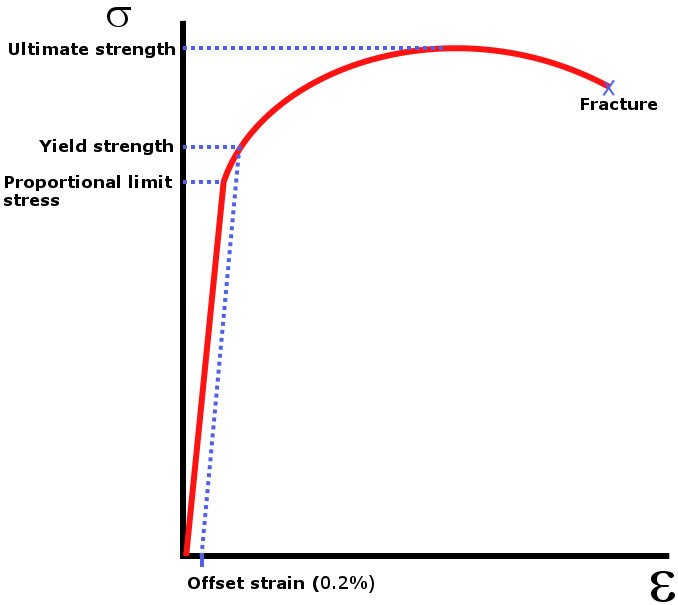

Many materials exhibit a linear elastic behavior, which means they become deformed (temporarily) when forces are applied on them, but return to their original shape once forces are no longer applied. This elastic behavior of materials usually extends to a certain point (called the ‘yield point’), up to which all deformations are reversible upon removal of the load.

Beyond the yield point, the deformations of ductile materials (like steel) are ‘plastic’. A plastically deformed sample does not completely return to its original shape and size when the load or stress is removed.

Beyond the yield point, the deformations of ductile materials (like steel) are ‘plastic’. A plastically deformed sample does not completely return to its original shape and size when the load or stress is removed.

Also Read: What Is The Stress-Strain Curve?

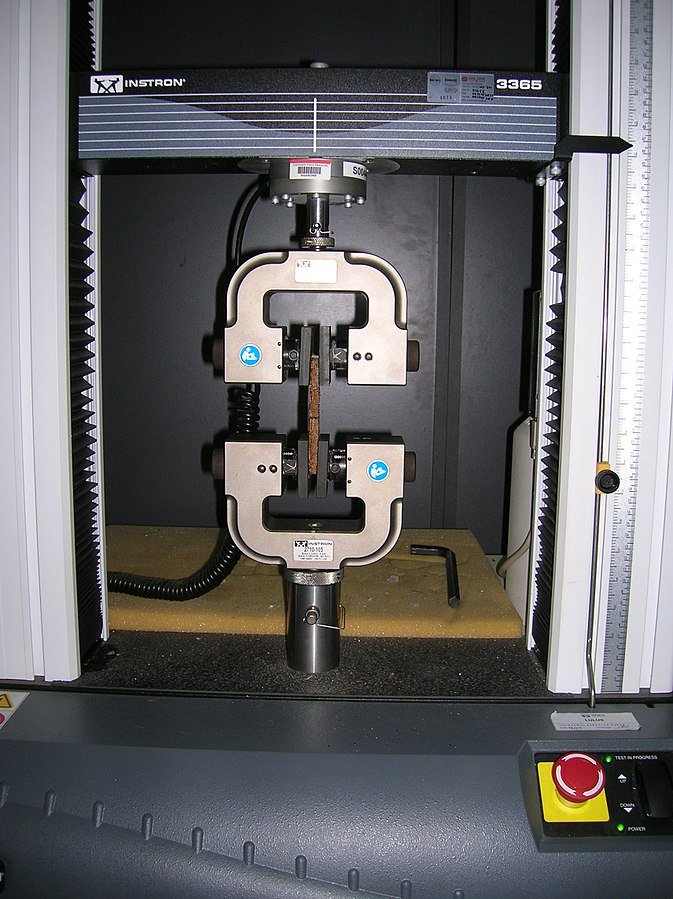

Tensile Testing

The ultimate tensile strength or UTS is therefore used for quality control (due to its ease of testing), to roughly determine material types for unknown samples.

Determining the UTS of a sample (i.e., a tensile test) is fairly simple. It involves using a small sample with a fixed cross-sectional area and then pulling it with a tensometer at a constant strain rate until the sample breaks. The highest point in the stress-strain curve (refer to the graph given above) is the ultimate tensile strength.

Since the UTS is an intensive property, its value is independent of the size of the test specimen; however, it depends on certain other factors, like the temperature of the material and the test environment, the presence of surface defects on the test specimen, preparation of the specimen etc.

Ultimate Tensile Strength Unit

Tensile strength is defined as a measurement of stress, which, in turn, is measured as force per unit area. The SI unit of UTS is Pascal or Pa. It’s usually expressed in megaPascals, so the UTS is commonly expressed in megaPascals (or MPa). In the US, the UTS is often expressed in pounds per square inch (or psi).

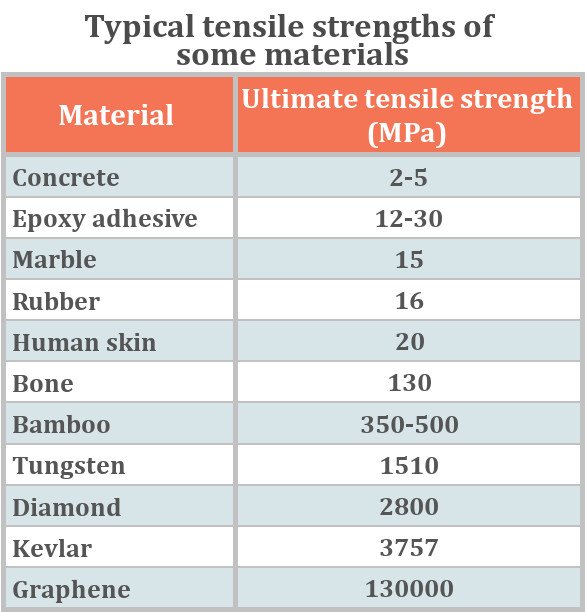

Ultimate Tensile Strength Of Some Common Materials

The ultimate tensile strength of a material is its maximum resistance to fracture. As you can imagine, the tensile strength of a material is a crucial measurement of its ability to perform in an application, which is why the UTS is widely used while describing the properties of alloys and metals.

Given below are the values of the UTS of a few materials:

As you can see in the table, concrete (a ‘hard’ object) has a lower UTS value than rubber, marble and even human skin. Diamond, quite predictably, appears near the bottom, and graphene, an allotrope of carbon, sits at the very bottom with the highest UTS value (in the table).

Also Read: Why Does Concrete Have Great Compressive Strength, But Poor Tensile Strength?

How much do you know about ultimate tensile strength?